Collection and Acceptance

of Hazardous Waste for a Safe and Clean Environment

Environmentally friendly treatment, storage, disposal, and recycling

We strictly adhere to regulatory requirements 100%

Nord Hazardous Waste takes care of the comprehensive and effective management of

hazardous waste generated by various industries, applying sustainable methods for

their solidification/stabilisation, utilisation and recycling.

Waste classified as hazardous comprises a wide range of waste products.

Their composition and properties have a substantial threat to human health and the environment.

Groups of hazardous waste

that we manage, solidify/stabilise and recycle

Our activity focuses on the collection, transportation, storage, utilisation and recycling of the following main groups:

Waste of agriculture, horticulture, aquaculture, forestry, hunting and fisherirs, food production and processing

Wastes, generated in agricultural and bio-production, such as Sludges from washing and cleaning, Animal-tissue waste, Waste plastics (except packaging),Wastes from chemical treatment etc

Wastes from the processing of wooden boards, veneers, chipboard, scraps containing various types of preservatives and others that can be hazardous to human health and nature

These wastes, after been processed, recycled or utilized in specialized for this activity recycling or processing plants, create an opportunity to reduce the needs of fresh wood material for various industries.

Waste related to the activity of the textile and leather industry

Various types of solvents and degreasers, dyes and pigments containing harmful substances, waste of treated or untreated textile fibers.

Wastes from petroleum refining, natural gas purifacation and pyrolytic treatment of coal

Waste originating from the production of energy carriers, made for the market. Those are gasoline, diesel, gas, as well as engine lubricating oils and greases, etc.

These wastes, in general possess both hazardous and non-hazardous properties and ingredients.

Waste of inorganic chemical processes

Waste products from acids, bases, salts, solutions or metal oxides. Waste containing metals and residues from the use of sulphur-containing chemical substances and preparations.

Waste of organic chemical processes

Waste products from plastics, synthetic rubber or artificial fibers. Organic based dyes and pigments. Waste of the production of laundry, cleaning and cosmetic preparations.

Wastes related to the manufacture, formulation, supply and use of coatings, adhesives and inks

Waste of substances and mixtures used to remove paints and varnishes containing organic solvents and other harmful substances.

Waste related to the activity of the photographic industry

Solutions from photographic developers and activators, disposable cameras with or without batteries, fixing solutions and others generated by photographic activity.

Waste related to the activity of power plants, combustion plants, foundries and others

Waste obtained as a result of thermal processes necessary for the production and processing of cast iron and steel products, incl. other metals – aluminum, lead, zinc, copper.

Waste products of chemical treatment and application of metal coatings, galvanizing and zink plating

They are mainly generated in the processes of galvanizing, zink plating and chemical cleaning of metal and other surfaces by means of phosphating, degreasing and the like.

Wastes from shaping, physical and mechanical surface treatment of metals and plastics

Wastes generated in the finishing or final processing of metal or plastic products, in grinding, cutting, polishing or other operations

Used oils

Used hydraulic, lubricating, motor, insulating, bilge and heat transfer lubricants.

Waste products from organic solvents

Waste from fluorochlorocarbons, fluorocarbons and other solvents and mixtures containing hazardous substances.

Packaging for storing dangerous substances, service fluids and absorbents

Various types of liquids and materials, such as absorbents, filters and filter materials. Metal and plastic boxes, packaging, foils and drums, incl. aerosol waste, tubes and the like.

Unusable vehicles, their parts, electronics and batteries

End-of-life vehicles and repair parts, electrical and electronic equipment, accumulators and batteries, as well as waste products from cleaning transport tanks.

Construction waste products containing hazardous substances

Materials used for insulation, incl. asbestos-containing building materials, including those composed of and/or containing harmful substances.

Waste generated by the activity of the waste processing industry

All types of waste products released after incineration and/or pyrolysis of waste, incl. regeneration of oily liquids.

Household waste (household and similar waste from commercial, industrial and administrative activities), including separately collected fractions

Waste originating from households, as well as from commercial, administrative or industrial activities. Household waste generated by daily and natural human activities at work or at home, including their separately collected fractions

Recycling process

The process of recycling, recovery or

disposal of hazardous waste includes the following operations:

Acceptance

Accepting hazardous waste from various

industries happens in two ways: by delivering

it to our acceptance points throughout the country or

by retrieving it on-site from the enterprise.

Checking the packaging and sorting

When received, the packaging of the waste is

checked to establish if it meets the

safety requirements for each type.

Then hazardous waste products are sorted by type.

Storage

Waste is kept in special storage units –

containment buildings and facilities,

designed with a special floor covering,

to guarantee its impermeability in cases of possible spills.

Transport

Transportation to the sites takes place

in special plastic bags or certified containers,

and from the sites to the recycling plant – with

specialized trucks that compile to the ADR regulations.

Recycling

Recycling depends on the technology

available and the composition of the waste.

Hazardous waste that cannot be recycled,

is sent for safety disposal or combustion.

Hazardous waste-controlled burning

Hazardous waste is burnt in specialized incinerator

systems at a very high temperature.

The produced energy is used by the cement plants

in our country.

Disposal

Packaging and waste in contact with hazardous

substances are treated using different methods.

As a result, safe recyclable resources – metals

and plastics – are obtained.

Benefits of recycling

The key mechanisms

Reducing

pollution

More

clean air and water

Less harmful

emissions in the atmosphere

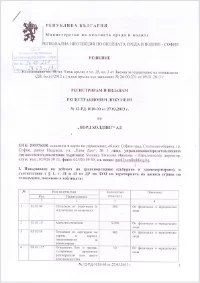

Permits held regarding the collection

and management of hazardous waste

Nord Holding has all necessary permits and

certificates for collection, storage, management and utilisation

of the collected groups of hazardous waste, including:

Standards applied to hazardous waste

In order to carry out its activity in the trading of hazardous waste, Nord Hazardous Waste applies the waste classification standards laid down by the EU and applicable to Bulgaria as a member of the EU.

The standards aim to unify the rules for classifying the different groups and types of hazardous waste according to their quality and composition.

Nord Hazardous Waste activity also complies with the standards of ISRI – Institute of Scrap Recycling Industries, regarding our activities in the management of non-ferrous and ferrous metal scrap.

The company holds established commercial positions both on the European and on the world market, which is based on the current international standards for quality and recycling of hazardous waste.

Damages from improper treatment of hazardous waste

The harms from the various groups of hazardous waste generated arise from their composition and properties. They appear when they come into contact with nature and/or with humans as a result of their improper treatment.

Their harmful impact can be expressed in the poisoning of water, soil or air, and hence in the irreversible pollution of flora and fauna. Toxic, corrosive and infectious processes also reflect on public health.

Hazardous waste enters the body and causes serious health problems either through the air, or through soil and/or water pollution and the subsequent use of natural resources by humans.

A precise approach to waste management

by Nord Hazardous Waste

How do we utilise and recycle different kinds of hazardous waste?

We offer sustainable solutions for the protection of nature and public health.

Vacuum

distillation

Waste service oils obtained after servicing cars, machines and others are transported in special tanks, barrels and other containers. The main method for their recycling is vacuum distillation, as a result of which different types of oils can be produced from them and/or used to make bituminous and asphalt pavement.

Incineration of hazardous

waste

Hazardous packaging, filters, absorbents, etc. from residual production are utilised through controlled burning in specialised incinerators. In the process, filters are used to capture harmful substances during combustion before they enter the atmosphere. The energy from combustion is also used as production power in cement plants.

Physico-chemical methods for solidification/stabilisation and recycling

A part of the used packaging (plastic and metal), classified as having been in contact with hazardous substances, is subject to solidification/stabilisation and recycling. Through the application of various physico-chemical methods, resources such as plastic and metal become suitable for subsequent production and use.